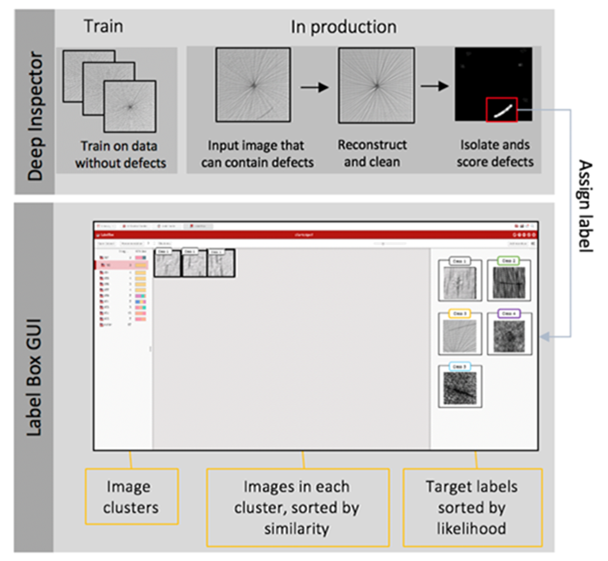

Visual inspection is the principal method adopted analysing visual data, usually in the form of images, with the purpose of identifying regions of interest. It involves the painstaking analysis of large quantities of data in order to find a very small number of regions of interest. In manufacturing, this approach is used to identify defective products or defective areas in a product. In infrastructure maintenance applications, it is used to find cracks in bridges or holes in the road, while in healthcare it can be used to find patches of unhealthy tissue. By automating visual inspection, analysis time can be greatly reduced and a substantial cost overhead removed. In addition, it delivers more consistent results, as a result of reducing the variation in results caused by different human interpretations. With regard to creating high quality datasets, the challenge centres around the very small number of regions of interest, involving high costs to inspect the very high numbers of images required in order to train an accurate AI model. For example, 100,000 images would need to be inspected in order to create a dataset containing 100 defects (average defect rate of 0/1%), and 1 million in order to create a more reasonable dataset with 1,000 regions of interest. Fujitsu Laboratories of Europe’s combined AI solution overcomes both of these issues, enabling high quality labelled datasets to be created rapidly and cost-effectively.

Fujitsu Laboratories of Europe’s CEO Dr Adel Rouz explains the significance of the new technology breakthrough, “This is the latest in a long line of Fujitsu’s novel AI technologies, applying our advanced data analytics and machine learning expertise to address complex non-intrusive testing applications. Once provided with a high volume of low-cost and easily available defect-free samples, our new defect detector technology is able rapidly to work out what to look for automatically. This simplifies and accelerates the creation of machine learning solutions, as well as enabling the detection of previously unknown anomalies. Combined with our new AI-assisted GUI, LabelGear, we have engineered a powerful new visual inspection tool that can be applied to a wide variety of tasks, reducing costs, improving accuracy and accelerating the overall process.”

Potential applications include manufacturing, where cameras are placed at key points on a production line, continuously monitoring product quality and identifying any potential defects. In the steel industry for example, where a 2km long steel coil is produced every hour, some 70,000 images are used to capture the surface of a single coil and over 1 million during the course of a day. With Fujitsu’s automated unsupervised solution, 80-90% of the defects can be automatically identified and assigned appropriate labels, covering around 200 types of defects that need to be recognised. Other potential applications include infrastructure monitoring and healthcare, where the solution can be used to diagnose and screen for abnormalities, such as chest abnormalities (using X-ray scans). In the US alone, around 150 million such health checks are performed each year. Manually labelling the enormous volume of resultant images is prohibitively costly and time-consuming but becomes feasible with Fujitsu’s automated unsupervised visual inspection technologies.